Kaiyuan Industry

Kaiyuan Industry

Zhejiang Kaiyuan New Wall Materials Co., Ltd. is a modern new wall material production enterprise invested and established by Kaiyuan Tourism Group in December 2004 in Linhang Industrial Park, Leidian Town, Deqing County. The total investment is RMB 200 million and the registered capital is RMB 9,170. Ten thousand yuan. The company covers an area of 100 acres and has more than 180 employees.

The company is mainly engaged in the research and development and production of aerated concrete (abbreviated as: AAC) products. It is a new type of environmentally friendly and energy-saving building materials produced by using ore dressing waste slag (powder) and chemical waste slag (desulfurization gypsum) as the main raw materials. The products are mainly B04, B05, B06 grade high-quality aerated concrete (AAC) blocks and reinforced panels and construction auxiliary materials have the advantages of lightweight, heat insulation, fire resistance, heat insulation, sound insulation, load bearing, earthquake resistance and radioactive non-existence. It is currently the mainstream new green building wall Body material products.

The company introduced fully automatic aerated concrete production line and proprietary production technology from WEHRHAHN, Germany. It is the earliest production line in the province with the ability to mix high-quality aerated concrete reinforced plates and blocks, with an annual design capacity of 400,000 cubic meters. , is an aerated concrete production line with a high level of technical equipment and a large-scale single production line. Its unique ground flip and six-sided cutting process enables all waste generated during the production process to be beaten and recycle, truly achieving zero pollution emissions. The project is a key technical transformation project in Zhejiang Province in 2005 and a resource conservation and environmental protection project in the National Development and Reform Commission in 2008, and received a central budget investment of 10 million yuan. The company has been successively rated as Zhejiang Province New Wall Material Demonstration Line (2006), National Advanced Enterprise for New Wall Materials (2008), Zhejiang Province Cleaning Production Enterprise (2011), Zhejiang Province New Wall Materials Leading Enterprise (2014), Zhejiang Province New Wall Materials The Chairman of the Wall Materials Association (2015), the National New Wall Materials Energy Conservation and Emission Reduction Demonstration Enterprise (2015), the National Building Materials Industry Enterprise with Remarkable Results in Transformation and Upgrading (2015), and the First National Advanced Collective for Science and Technology Innovation in the Aerated Concrete Industry (2015) , the company's autoclaved aerated concrete blocks/slabs were rated as national three-star green building materials (2017).

The company participates in the formulation of a number of national and provincial targets. The company is the Zhejiang Provincial Building Standard Design Collection "Detailed Structure of Autoclaved Sand Aerated Concrete (AAC) Slab" (2010 Zhejiang G33), and "Detailed Structure of Autoclaved Sand Aerated Concrete (AAC) Blocks" (2010 Zhejiang G34 ) Editor-in-chief unit, which is the national standards "Autopressed aerated concrete blocks and plate structure" (13J104), "Autopressed aerated concrete slabs" (GB 15762-2008), and "Autopressed aerated concrete performance test method" (GB /T11969-2008), Zhejiang Province's engineering construction standards "Technical Regulations on the Application of Autoclaved Sand Aerated Concrete Blocks" (DB33/T1022-2005) and "Comprehensive Energy Consumption Limit and Calculation Method for Unit Products of Autoclaved Aerated Concrete Blocks" (DB33/866-2013) Participated in the unit.

At present, the company has four major system certifications: quality management system, environmental management system, occupational health and safety system and energy management system, and has established complete production process regulations and enterprise standards. The products produced by the company have received unanimous praise from the market.

Changzhou Aborl New Material Technology Co.,Ltd

Brand: Aborl

Main Products: Spc Flooring , Plastic Flooring , Wood Flooring , Laminate Flooring , Engineered Flooring , PVC Flooring

Brand: YOKETOOL DIAMOND

Main Products: Diamond Core Drill Bits , Diamond Saw Blades , Construction Drill Bits , Wet Diamond Core Bits , Dry Diamond Core Bits , Masonry and Concrete Drilling Bits

Jiangyin Dego Building Materials Co., Ltd.

Brand: Degoceiling

Main Products: Seamless acoustic ceiling , acoustic panels , ceiling panel , Rockwool ceiling , acoustic plaster , acoustic ceiling tile

Hebei Zhuheng Technology Co., Ltd.

Brand: ZHUHENG DUNPAI®、ZHUHENG YIJIA®、Conmsperm™

Main Products: Window Tapes , Waterproof Air-tight Tapes , Adhesives and Sealants , Specialty Waterproof Coating , Corner Patch , Pre-compressed Joint Sealing Tapes

Hebei RooAoo New Material Technology Co.,Ltd.

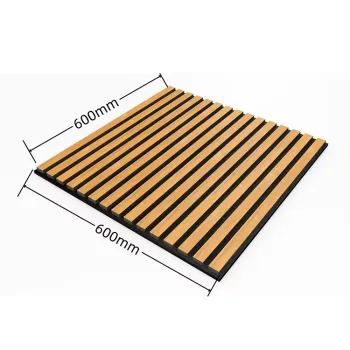

Brand: RooAoo

Main Products: Akupanel , Acoustic Panel , 3D Wall Panel , Felt Bin Board , Acoustic Divider , Wood Slat Panel

Guangzhou Mingli Intelligent Equipment Co.,Ltd

Brand: iBooth

Main Products: Mobile Soundproof Booth , Portable Office Meeting Pods , Movable Soundproof Room , Silence Room Box , Removable Acoustic Room , Office Pods